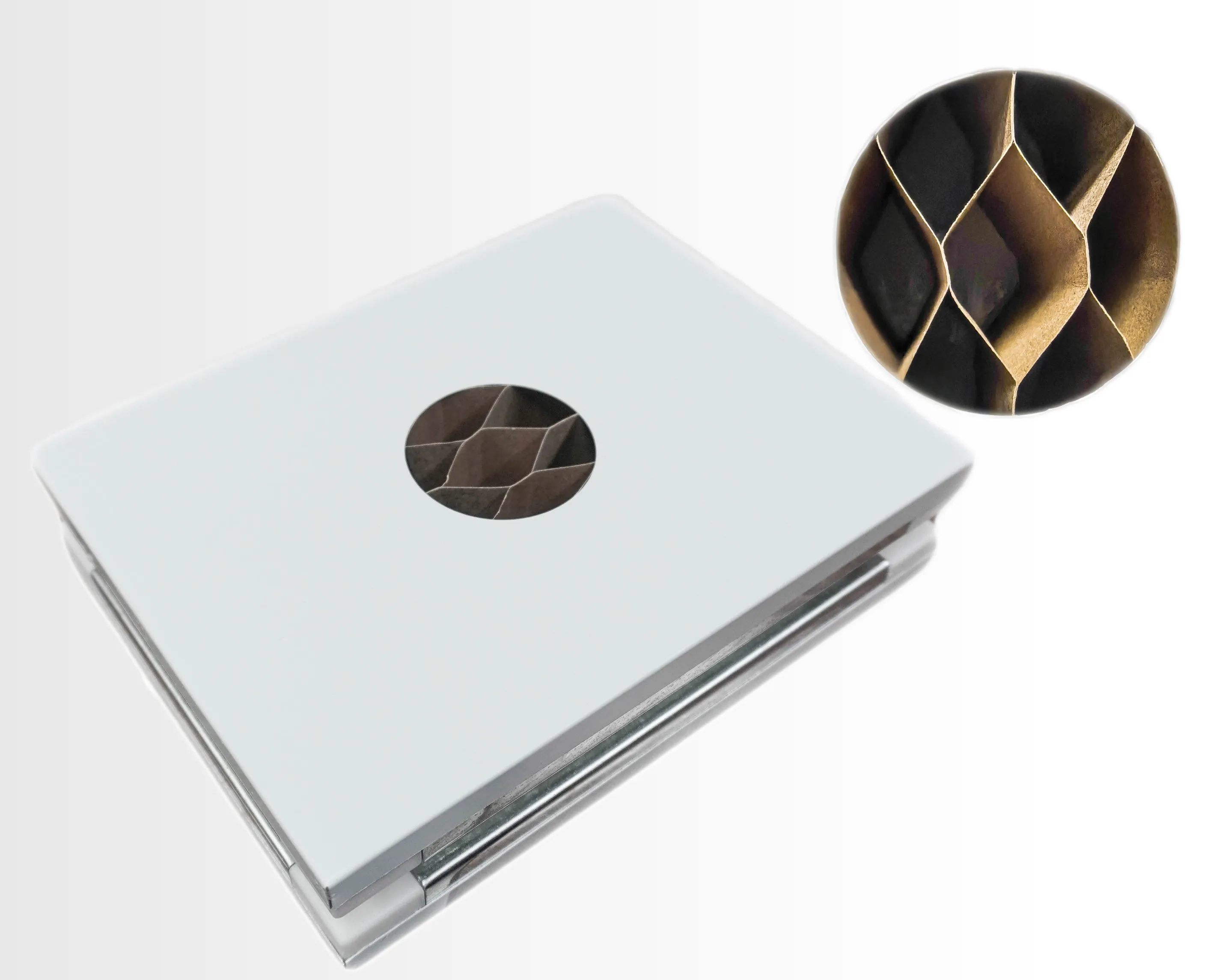

Handmade Paper Honeycomb Sandwich Panel

Handmade Paper Honeycomb Sandwich Panel can be customized with different surface layers (GI, PPGI or SS), it surrounded by galvanized keel steel frame to enhance airtightness and structural strength.

Paper honeycomb sandwich panels use flame-retardant paper as the core material and have a hexagonal honeycomb structure, which can effectively insulate sound. They are also light in structure and easier to carry and cut manually, which can reduce construction costs and time.

|

Name: |

Handmade Paper Honeycomb Sandwich Panel |

|

Panel thickness: |

50mm, 75mm, 100mm |

|

Effective Width: |

980mm, 1180mm |

|

Panel Width: |

1000mm,1200mm |

|

Panel Surface: |

PE, PVDF (fluorocarbon), Al-mg-Mn Alloy Steel, Saltized board, antistatic, Stainless Steel |

|

Panel Surface thickness: |

0.4-0.6mm |

|

Core Material: |

Paper Honeycomb |

|

Connection method : |

Central Aluminum Connection & male and female Socket Connection |

Unlike machine-made panels, handmade sandwich panels are semi-automated but rely on manual craftsmanship for key steps such as adhesive application, core placement, and edge finishing. While both types offer fire resistance, sound insulation, and thermal insulation, handmade panels provide superior strength and airtightness due to their reinforced structure and specialized jointing method.

They offer exceptional surface flatness for an aesthetically pleasing appearance and can be fully customized to non-standard sizes, adapting to complex designs while reducing on-site cutting waste.

Smooth, seamless surface minimizes dust accumulation and

allows easy sterilization, meeting stringent cleanroom hygiene standards.

2. Superior Thermal & Acoustic InsulationRock wool offers superior sound insulation performance.

PU/PIR cores provide high thermal resistance (low U-value), reducing

energy costs.3. Excellent Fire Resistance

Core materials with different fire protection levels from A1 to B1/B2

4. Superior Dustproof & Antimicrobial Properties

Special coatings or antimicrobial materials inhibit bacterial growth,

making them ideal for medical, electronics, and other sensitive

industries.

5. Modular & Easy InstallationStandardized modular design enables fast assembly, reducing labor

costs and facilitating maintenance.

6. Eco-friendlyThermal/acoustic insulation cores reduce energy consumption, with

recyclable materials aligning with green building practices.

Ensures stable and contamination-free experimental environments.

• Pharmaceutical Cleanrooms (GMP Facilities)

Used for walls & ceilings in pharmaceutical production, meeting strict requirements for

fireproofing,moisture resistance, and antimicrobial properties.

• High-Precision Electronics & Biotech LabsProvides ultra-clean conditions for sensitive manufacturing and research.

• Chemical Explosion-Proof Workshops

Enhanced structural integrity and sealing for hazardous environments

CONTACT US

Accompanying you from start to success

Connnect with us!