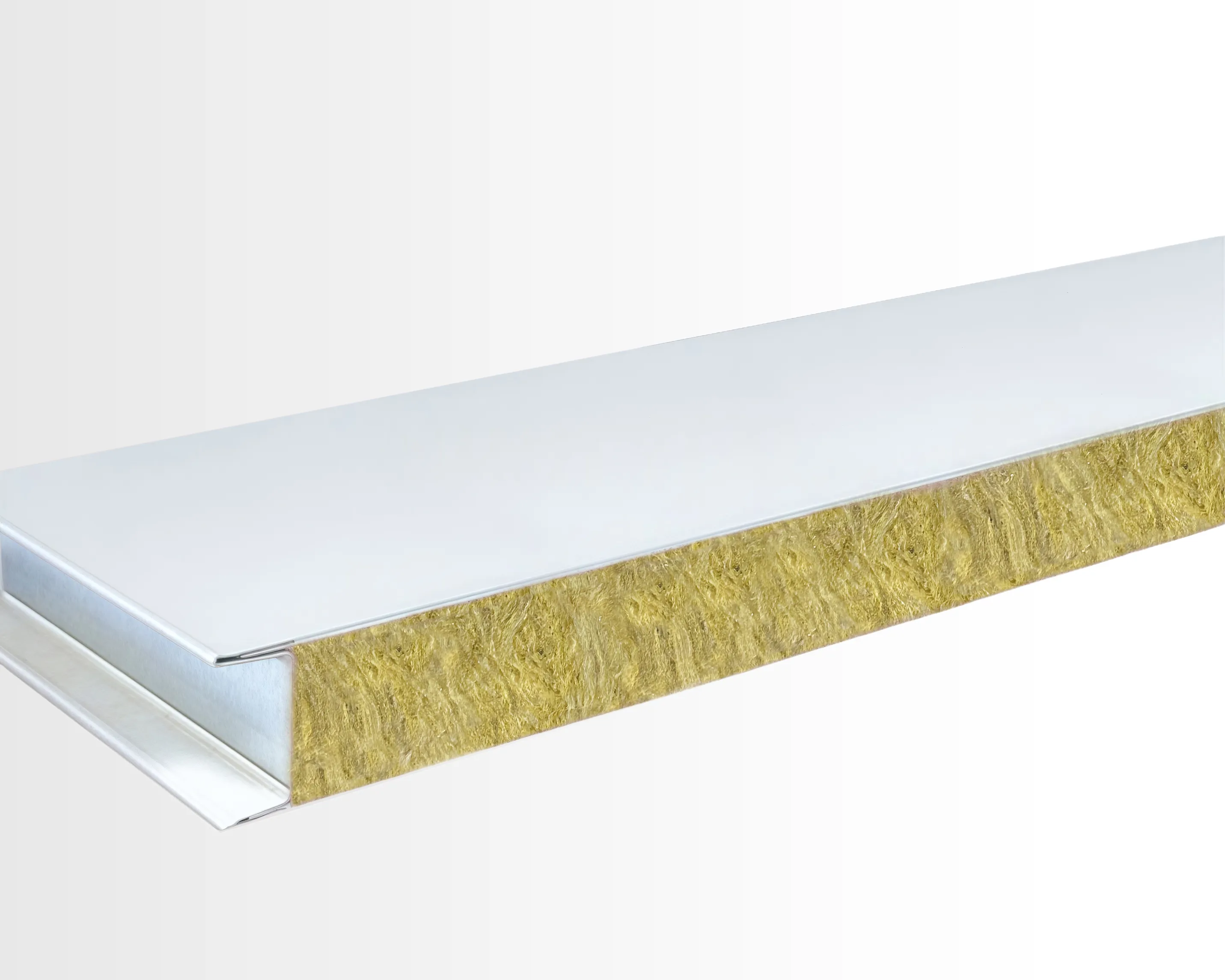

Machine-made Rockwool Sandwich Panel

Machine-made rockwool sandwich panels use pre-painted galvanized steel sheets or stainless steel sheets as double-sided surfaces, rockwool as infill. With the advantages of best fire and sound resistance ability, rockwool sandwich panels are the most widely used in cleanroom construction, normally as cleanroom wall panels.

|

Product Name: |

Machine-made Rockwool Sandwich Panel |

|

Panel Thickness: |

50mm, 75mm, 100mm, 120mm, 150mm, 200mm |

|

Panel Width: |

1000mm, 1200mm |

|

Effective Width: |

950mm, 1150mm |

|

Panel Surface: |

PE, PVDF (fluorocarbon), Al-mg-Mn Alloy Steel, Saltized board, antistatic, Stainless Steel |

|

Panel Surface thickness: |

0.4-0.6mm |

|

Core Material: |

Rock Wool |

|

Connection Method : |

Tongue-and-groove splicing |

Smooth, seamless surface minimizes dust accumulation and

allows easy sterilization, meeting stringent cleanroom hygiene standards.

2. Superior Thermal & Acoustic InsulationRock wool offers superior sound insulation performance.

PU/PIR cores provide high thermal resistance (low U-value), reducing

energy costs.3. Excellent Fire Resistance

Core materials with different fire protection levels from A1 to B1/B2

4. Superior Dustproof & Antimicrobial Properties

Special coatings or antimicrobial materials inhibit bacterial growth,

making them ideal for medical, electronics, and other sensitive

industries.

5. Modular & Easy InstallationStandardized modular design enables fast assembly, reducing labor

costs and facilitating maintenance.

6. Eco-friendlyThermal/acoustic insulation cores reduce energy consumption, with

recyclable materials aligning with green building practices.

Depending on the core material and surface steel plate composition, these panels provide different functionalities, such as:

Rock wool core panels: Exceptional fire resistance, thermal insulation, and sound absorption.

PU/PIR core panels: Outstanding thermal insulation, helping reduce energy consumption.

Magnesium oxysulfide core panels: High strength and fireproof performance.

CONTACT US

Accompanying you from start to success

Connnect with us!